Frequently Asked Questions

We answer your questions about our process, timelines and way of working. Here you will find clear answers on how we design, develop and implement solutions for your operations.

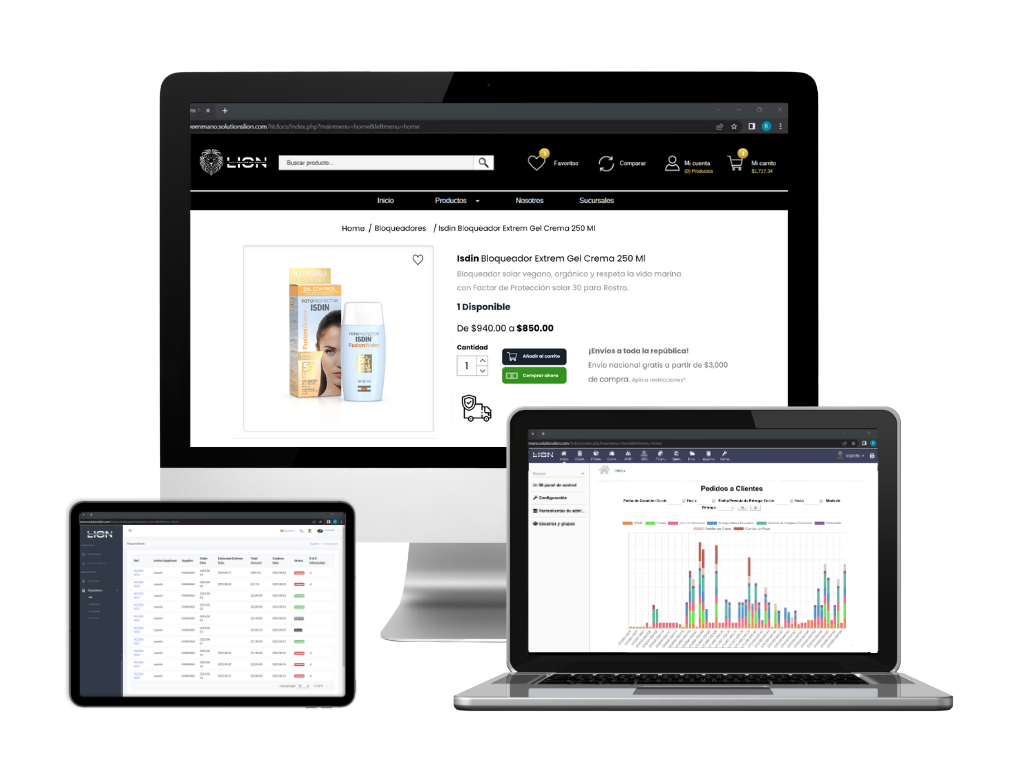

At Lionologies Solutions, we convert real-world processes, operational rules and complex challenges into stable systems that perform from day one. We don't just build software on demand: we design technology aligned with how your business operates.

With over 15 years of experience and projects across more than 23 industries, we have built architectures, integrated industrial hardware and applied advanced technologies to create mature, scalable solutions fully aligned with real-world operations.

Languages & Frameworks Selected based on the real needs of each process

Applied technologies

IoT, VR/MR, industrial SDKs, advanced APIs and integrations

Specialized Add-ons Microservices, connectors, algorithms & proprietary engines

Transformed industries Operational experience converted into functional solutions

We begin by understanding how each client operates and what they need to solve. We analyze their on-site processes, identify friction points and design a clear path to translate them into a functional solution.

That is why our implementations are not templates: they are architectures designed over real processes, field-tested and ready to evolve.

Developed solutions Implemented and running in daily operations

Successful integrations Connections between industrial hardware & software

They recommend us

These testimonials aren't just about us; they are about how we solve real-world problems, integrate useful technology, and ensure operations run with greater clarity, stability and efficiency. Each experience reflects projects where we transformed processes, digitized critical workflows and connected people, equipment and systems with precision.

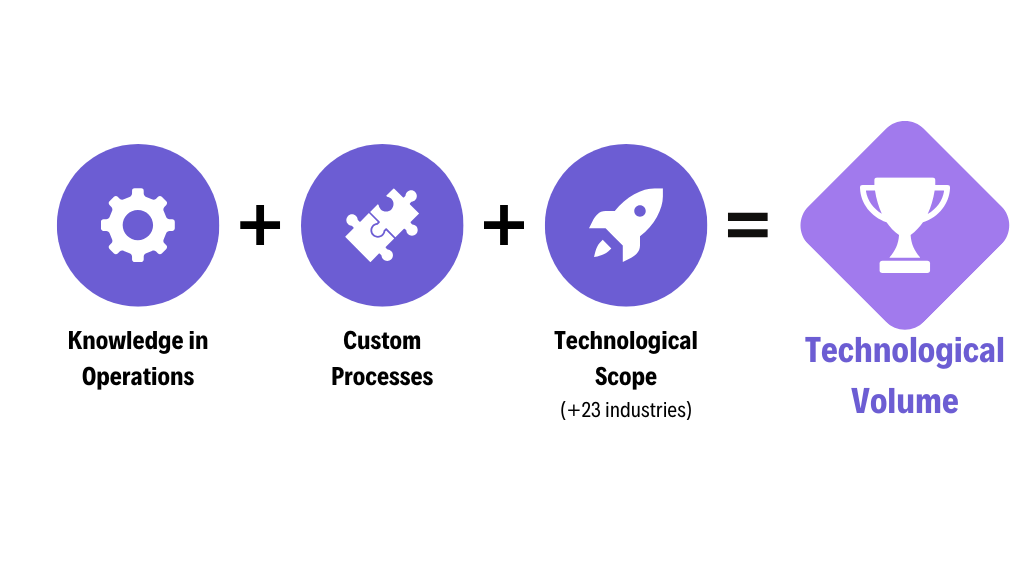

How do we help you achieve it?

We identify the exact technology your process needs to solve its operational challenges.

We create tailor-made solutions fully aligned with your processes, rules and strategic goals.

We prepare your team to use digital tools fluently, ensuring full organizational adoption.

We institutionalize your operational rules and design systems capable of growing with you.

We optimize current developments, modernize architectures and eliminate friction points.

We reduce operational workload and human-factor dependency while increasing precision.

We consolidate data from multiple areas to enable strategic decisions based on real information.

We adapt your systems to operate across multiple platforms, devices and environments.

Because we solve real-world operations. Our approach goes beyond software development: we build solutions that reduce errors, synchronize processes and automate critical tasks so your operation runs with greater clarity, stability and efficiency.

Every system is born from a deep understanding of your business. We analyze rules, workflows and friction points to transform them into stable, scalable architectures that are perfectly integrated with your way of operating.

We don't just "connect" systems: we integrate software, hardware, IoT, mobile platforms and data into a unified ecosystem. And most importantly: the technology we develop is completely yours. The intellectual property belongs to the client, guaranteeing independence, transparency and growth without restrictions.

We build ecosystems that automate, synchronize and strengthen your operations from initial analysis to final implementation. We are the partner that understands how you work and executes alongside you.

Let's talk about your projectWe answer your questions about our process, timelines and way of working. Here you will find clear answers on how we design, develop and implement solutions for your operations.

We begin with a diagnostic session where we analyze your real-world operations and identify friction points. With this information, we build a functional prototype that simulates screens, workflows and operational rules.

This prototype is validated with you before discussing costs. Once confirmed, we present a technical proposal including timelines and investment. We then move forward with full design, staged development and integration into real-world scenarios.

Because we don't develop based on assumptions: we design starting from an interactive prototype validated by you. This prototype includes screens, workflows, rules and operational logic.

Only after validating how the system should function do we begin development, ensuring the final solution reflects your real processes and integrates with your existing systems.

It depends on the scope, complexity and level of integration. Following the diagnosis and prototype validation, we provide a staged timeline, a clear implementation roadmap and a precise investment plan.

Our goal is to provide total visibility from the start and ensure the investment is aligned with the operational value you will receive.